Time, material waste and labor efficiency are often top of mind for manufacturers.

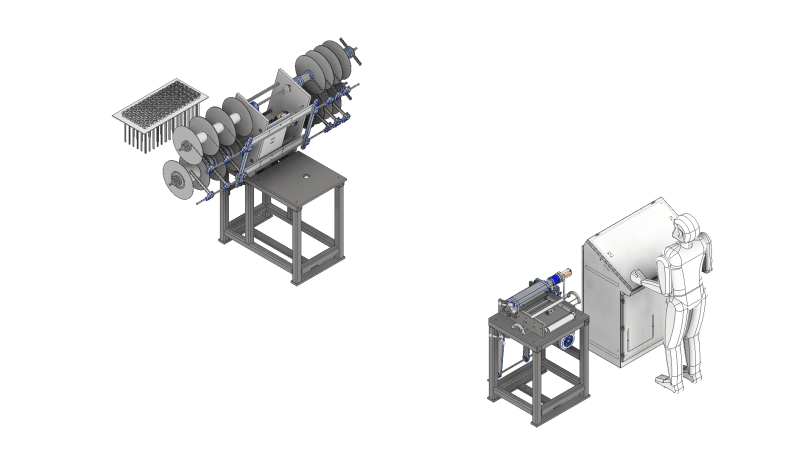

Minland Machine’s new automated quick-change razor blade cutting assembly is a next-level solution for RV, automotive and gasket producers seeking precision results.

This custom cutting assembly allows for accurate and repeatable cuts of tape in widths ranging from 1/4 inch to 1 inch, with accuracy up +/-0.005.

On the winder, guides are easily adjustable up to 1 inch at 1/8-inch increments, with smooth changeover achieved by chain pull pins, enabling rapid cycling between material widths. With controls designed by Minland Machine partner Envision Automation, the assembly is virtually unlimited in programmability.

How the Machine Helps

Our client’s previous tape-cutting machinery required 30–60 minutes of manual changeover time, including sluggish unbolting and bolting and spacing of blades by hand.

With our new machine, the blade-adjustment process is complete in seconds.

In a manufacturing environment, there are several potential benefits from this new technology. First and foremost, the automated quick-change blade cutting assembly increases production speed and accuracy significantly. It eliminates tedious, manual labor, thus reducing errors that can lead to costly rework or scrapped parts. Additionally, its precision offers manufacturers more control over their output quality than traditional methods; this makes it easier for them to meet customer requirements and standards for their products’ appearance and performance.

The automated quick-change razor blade cutting assembly also reduces waste of time and material; strips of single- or double-sided tape that adheres to foam sealers or gaskets can be exactly cut without excess material beyond what is needed for each task. Its unique design also allows users to replace razor blades with ease, boosting operational efficiency and limiting downtime. This provides greater flexibility when responding quickly to job specifics and minimizes stops in production.

Furthermore, the machine does not require any special knowledge or extensive training for operators since it comes preprogrammed with automated processes based on designs given by Envision Automation, a collaborator of Minland Machine; all users need to do is enter parameters such as desired dimensions and number of cuts required into the system before beginning a job.

This tape-cutting assembly offers tremendous value for RV producers and other manufacturers looking for faster turnaround times, higher-precision cuts, greater flexibility in responding quickly to job specs, significant cost savings due to minimal material waste, reduced reliance on manual handling of hazardous equipment and easy operability — all backed up by trusted support available around the clock from experienced technicians.

The bottom line? Our automated tape cutting machine is faster, more accurate, less costly and safer than manual methods while offering greater flexibility due to its programmable capabilities.

Contact us today to learn how our engineering team can custom design and build a tape-cutting assembly to meet your manufacturing needs while bolstering your operational success!