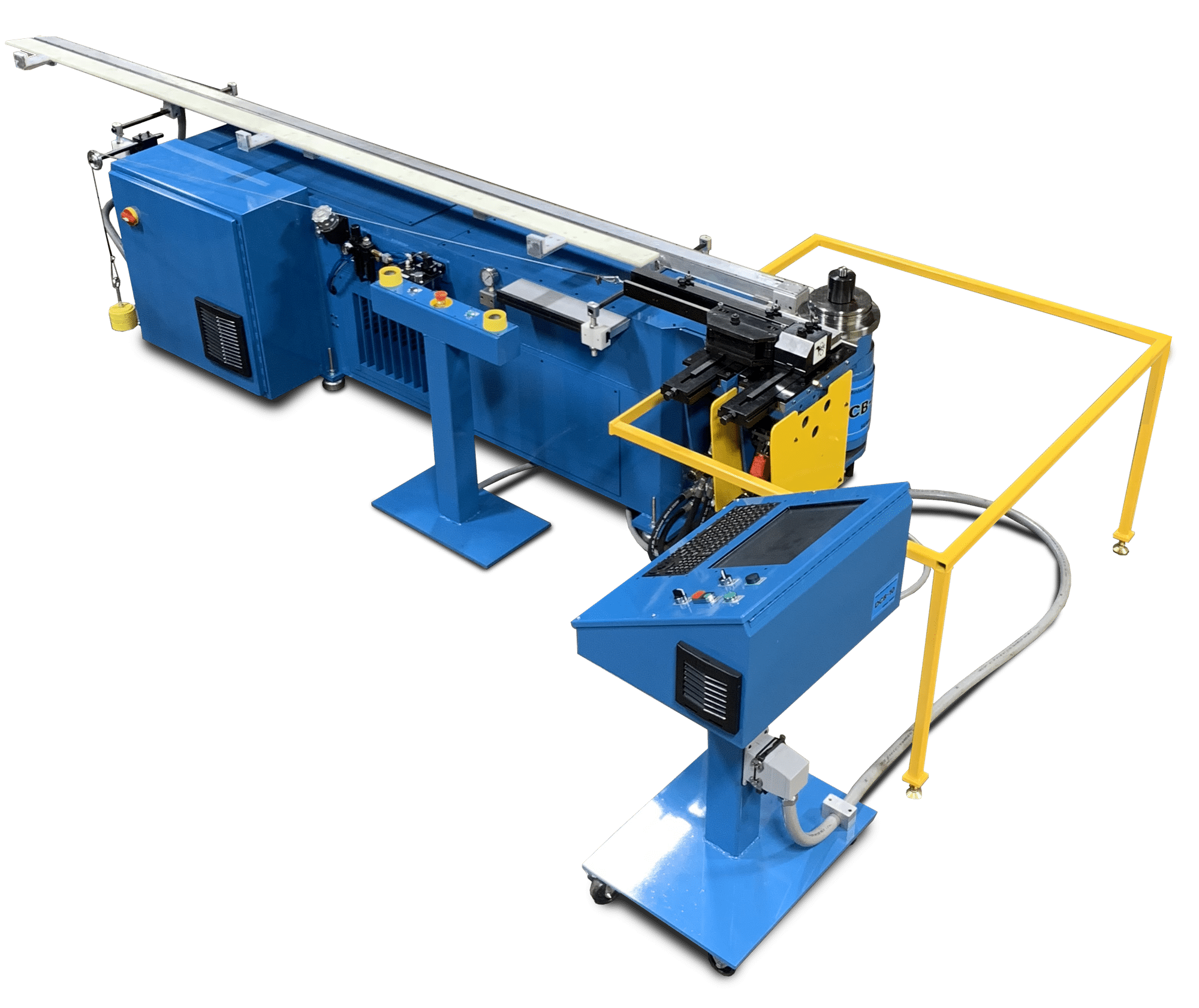

DCB10 Bender

Our most popular product is our CNC-controlled window extrusion bender. Available with single-stop and multi-stop tables. Engineered to suit your most difficult bends; optimized for operator safety and efficiency.

Why use the DCB10 Bender

Multiple custom Benders targeted to the bending of aluminum extrusion profiles. Our Benders out perform competitors with Quicker Change Over, Faster Setup Times, and Less Scrap Rate.

Mandrel

Attachment Option

Quick Change

Follow Bars

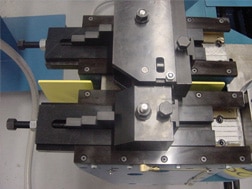

Quick Change

Clamp Tooling

Quick Change

Clamp Tooling (2)

Machine Features

- Easy to Use 800×600 Touch Screen GUI

- Full Industrial keyboard\Mouse

- Unlimited program storage

- Incremental/Absolute programming Modes

- Quick-Change Tooling System

- Split Die Actuator

- Mandrel Attachment (optional)

- 20 ft. Servo Stop Table travel

- Multi-Stage Stop Table (optional)

- Table may be ordered in shorter lengths

- Dual Swing-arm safety plates

- Auto-lube System

- External Network Connection standard

- External USB port

- 240/40amp or 480/25amp 3ph Main Power

Software Features

- Windows 10 Pro Operating System

- 12 Programmable Bend settings with adjustable Bend Speeds for each bend

- Programmable Stop Settings (with Global increase/decrease)

- Load/Save/Edit Part Programs

- Program Notes and DXF Drawings for Operator Reference

- Online Machine Maintenance records

- Program change log and Production reports

- Online help screens and operators manual

- Software security system to prevent unauthorized users from making changes to part programs

DCB10 Bender Options

Option 1: Standard Stop Table

- The Standard Linear Stop Table uses a single stop with infinite positioning Advantage over the Multi-Stage Stop Table

- Slight Cost Savings

Option 2: Multi-Stage Stop Table

The Standard Linear Stop Table uses a single stop with infinite positioning Advantage over the Multi-Stage Stop Table.

Each Stop is automatically positioned at the start of the cycle. Table can have up to 12 stops. If your Part program requires less stops than the number of total stops the unused stops are sent to rear home positions and the software automatically positions the remaining stops as normal.

- Faster Production – no waiting for stop to indexing between each bend cycle

- Safety – The stop does not have to move during production.

- Less wear means better Stop Table life

Need CNC Expertise?

Minland Machine utilizes the best equipment, technology, and people to produce the highest quality CNC machining in the industry. Contact us for your next project.